ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Every senior photographer knows that stability is the prerequisite for shooting, so a tripod came into being. Its fundamental purpose is to increase and ensure the stability of shooting. How the small laser tube cutting machines balance materials, stabilize structures, and assemble precisely, which are the core of the design and manufacture of the tripod.

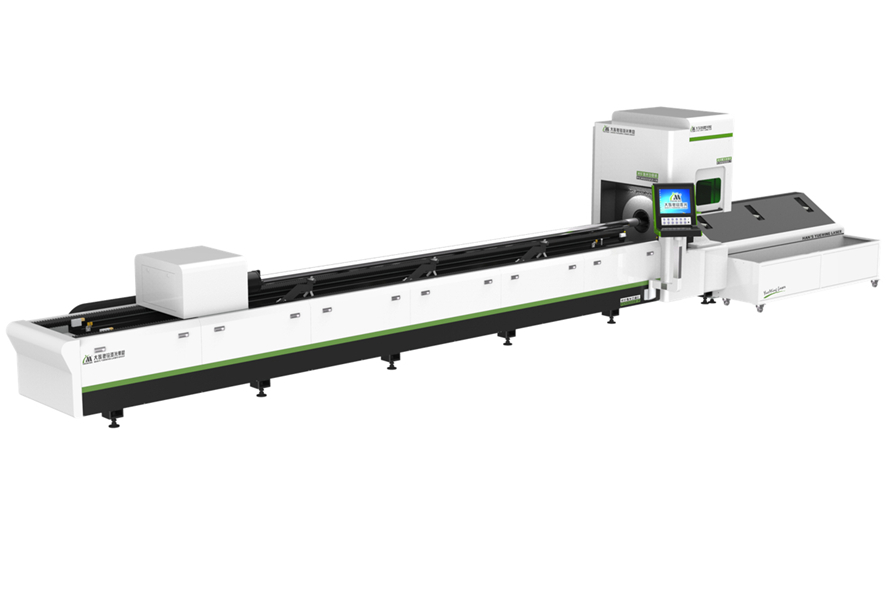

A good tripod is the combination of materials and technology. Tripod processing requires the cutting of metal pipes. Common materials such as aluminum alloy and stainless steel. The small laser tube cutting machine adopts CNC automatic processing method. It has been unanimously praised by metal tube processing manufacturers and has become a standard equipment in the manufacturing process of the photographic equipment industry with its characteristics of high-speed, high-efficiency, lower investment and higher output.

The diameter of the tube frame determines the weight of the tripod. The thicker the tube diameter, the more stable it is, and the thinner the tube diameter, the more portable it is. The use of a small laser pipe cutting machine does not need to open the mold. Also, it can be adapted to the cutting of pipes of different diameters, and does not need to make molds for different designs, which saves a lot of production costs for manufacturers.

The surface of laser is smooth and burr-free. Secondary processing is not required, which shortens the production period of the tripod. As the heat-affected zone is small, there is no need to worry about deformation. Most of the photography tripods are retractable. The internal structure of the tripod and the components are perfectly matched to ensure the stability while use.

Recommend

1. Features

(1) Equipped with pneumatic auto-centering chuck, precise and simple to use, easy for Square tube, round tube, oval tube, flat tube, triangular tube and profile steel cutting;

(2) Intensive classis with high rigidity has high precision and stability effectively eliminating the shock in high-speed cutting;

(3) Large gantry milling machine, tempering treatment and vibration aging to eliminate stress, its geometric accuracy is within 0.03mm;

(4) Germany IPG laser generator has high wall-plug efficiency over 30%,greatly saving power and achieving the highest efficiency;

(5) Auto-focus laser cutting head, integrates with detailed cutting parameters, easy for operation;

(6) Cutting head has the leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

(7) The cutting head directly locates the center of the pipe, high efficiency performance;

(8) Professional nesting software, with power control, fast piercing and sharp corner processing function

2. Materials

Apply to various pipes such as round pipe, square pipe, flat pipe, U-shaped pipe, channel steel, and other steel profile

PREVIOUS: What you have to know about the hoodie film cutting machine

NEXT: The price of laser marking machines is competitive as its high-speed marking of product information

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...