ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

The important role of carpet as floor decoration

Can be used for home space, car interior, hotel environment, corporate facade, etc.

Bring good visual effects

Carpets of different colors, materials and sizes

Are the most unique existence in the space

Introduce carpet laser engraving machine in carpet manufacturing

Is a "new bright spot" in the carpet processing market in recent years

Carpet laser engraving machine eliminates the traditional production process of grinding, hot stamping, embossing and other processing

Laser printing is formed at one time, with high definition and strong three-dimensional effect

Fully express the natural texture of various fabrics

The marked groove can also increase friction to avoid slipping

Realize diversified designs in the limited space of carpet

Easily enhance the sense and taste of interior space design

To meet the different aesthetics of different people and the use needs of different places

Exclusive customization has become the default demand in the personalized era

Carpet laser engraving machine can be designed according to individual characters and special patterns

Create a "unique" home carpet for users

Or customize the company trademark logo and welcome words on the carpet

Not only can play a role in publicity

It can also improve the image of the company and store

Recommended equipment

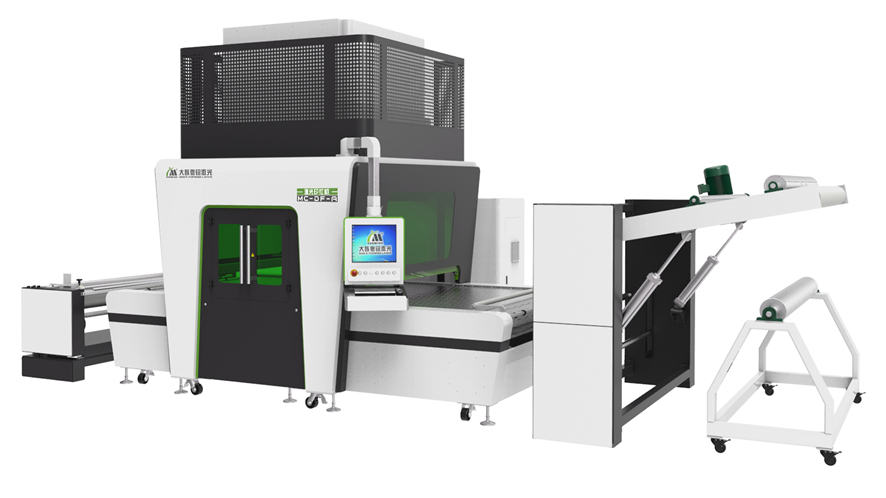

Large format seamless splicing flying laser printing machine MC-DF-A

1 Features

◆In the process of conveying materials on the conveyor line, the control system realizes 1800mm* infinitely long large-format flight tracking laser printing through the control of the laser light, the trajectory of the scanning head movement pattern and the movement speed of the conveyor line;

◆Automatic rewinding and unwinding function: modularized design of the automated rewinding and unwinding system, the entire processing process only needs to be supervised by the operator, realizing the industry 4.0 idea of one person and multiple machines, greatly improving product processing efficiency;

◆Correction system: During the movement of automatic rewinding and unwinding, the deviation correction system is used to correct the deviation caused by the movement of the material to achieve high-precision flight graphics splicing accuracy;

◆Meter counting function: After the marking is completed, the meter counter can accurately calculate the length of the whole roll of processed material, integrate the function of the cloth measuring machine, and effectively reduce the profit loss caused by the increase of the number of coil meters in the factory;

◆Conveyor belt: The carpet laser engraving machine adopts a custom-made stainless steel punching chain conveyor belt and a conveying system composed of a hydrodynamic analysis adsorption structure, which has large adsorption force and stable operation.

2Applicable materials for this laser marking machine

Natural and artificial (chemical fiber) fabrics, real leather and artificial leather.

PREVIOUS: Laser engraved new ice tartar, creating the coolest summer beauty.

NEXT: Kitchenware industry processing weapon-sheet metal kitchenware laser cutting machine

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...