ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Laser welding machine is a very popular welding equipment in recent years. For many manufacturers still using argon arc welding, laser welding machine equipment is a new thing, it is a new type of welding equipment that we want to try. Today, we are introducing the advantages of laser welding machine equipment to answer questions for manufacturers who are still hesitating.

High production efficiency: the laser welding speed is fast, the penetration depth is relatively deep, and the welding yield of different materials is high, which is 2-10 times faster than traditional welding speed. Equipped with water cooling equipment to ensure continuous work for 24 hours.

Safer and more environmentally friendly: Laser welding is environmentally friendly and safe. Traditional argon arc welding generates a large amount of welding dust and slag, which is more harmful to the environment, while laser handheld welding is relatively less harmful to the environment.

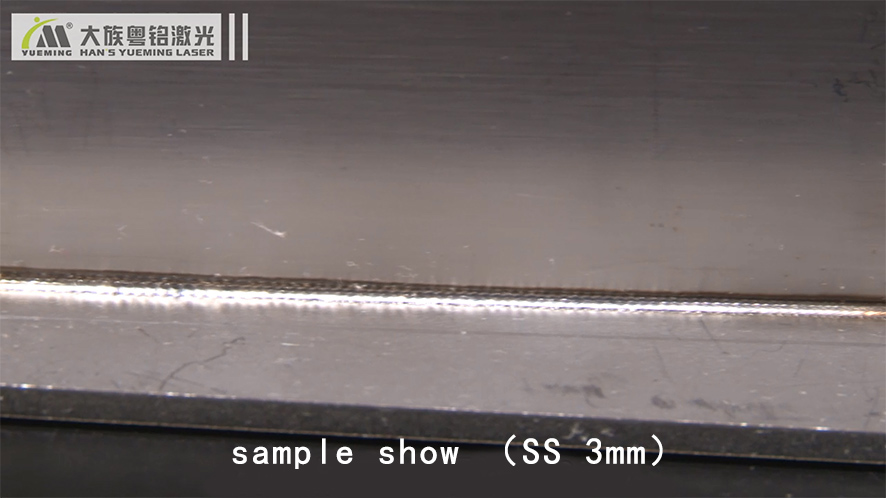

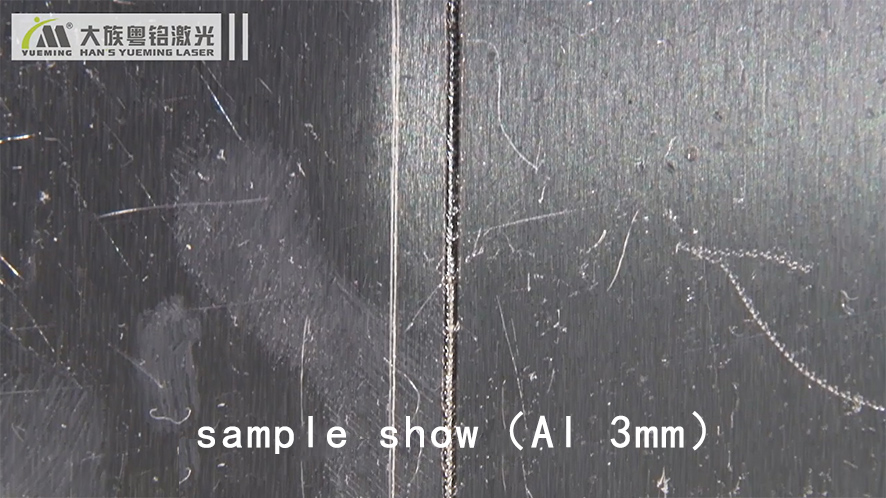

Welding is more beautiful: the heat affected area is small during welding, the workpiece has no deformation, no welding scars, the welding is firm, smooth and beautiful, and the subsequent grinding process is reduced.

Low labor cost: Taking argon arc welding as an example, argon arc welding requires mature welders, while handheld laser welding only requires ordinary operators and can learn to work in 30 minutes. The annual labor cost of a mature welder is higher than that of ordinary operators. According to the calculation of the efficiency of the handheld laser welding machine is twice that of argon arc welding, the labor cost savings can also be doubled. In addition, argon arc welding generally requires grinding after welding, and handheld laser welding requires little or no need for grinding, which saves part of the labor cost of grinding.

Handheld laser welding machine

Laser welding machine equipment can be used in cabinets, cabinets, kitchen cabinets, stainless steel doors and windows, metal products, advertising signs, craft products, battery components, steel furniture, shelves and other fields such as sheet metal, chassis, water tanks, distribution boxes and other cabinets. In terms of materials, the laser welding machine equipment can be used for welding the same material of various metal sheets such as aluminum sheet, iron sheet, stainless steel sheet, copper sheet and so on. And a variety of materials such as aluminum and copper, stainless steel and copper are welded together.Included in the field of argon arc welding.

NEXT: Different smart wearable devices, not ordinary laser micro-hole processing technology.

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...