ec@ymlaser.com

+86 139 2589 8201

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

- Web

By : Han's Yueming Laser Group Share: Back to list

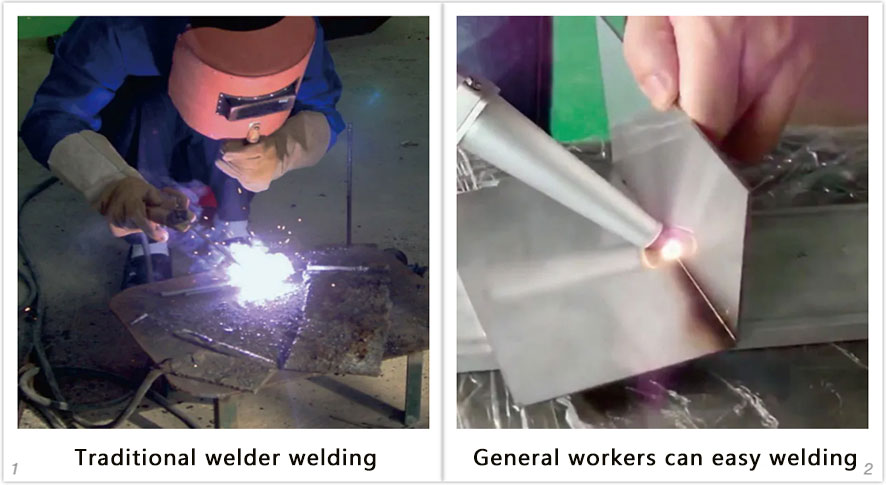

For welding, in your impression, this is probably the case. Welders wearing insulating shoes and thick gloves at the sparking welding site are holding a protective mask and holding heavy welding tongs. This welding method is used in cabinets, kitchen cabinets, stainless steel doors and windows and other fields such as sheet metal, cabinets, water tanks and distribution boxes. Now, in these welding application scenarios, this traditional welding method that is not safe, not environmentally friendly, not efficient, not convenient, and not beautiful will be gradually adopted by the upgraded version of the handheld laser welding machine (HW-A) launched by Han's Yueming Laser Group instead. Now companies are using highly efficient and environmentally friendly handheld laser welding machines. No wonder they are so profitable.

(Model recommendation: handheld laser welding machine HW-A )

01 Features:

u Metal plate welding

u Integrated and convenient design

u Ergonomic hand-held welding head

u No need to add welding wire, the welding is firmer

u General workers can operate after training, without the need for professional welders

u Energy saving, power consumption is less than 1.5 degrees / hour

( General workers can easily weld)

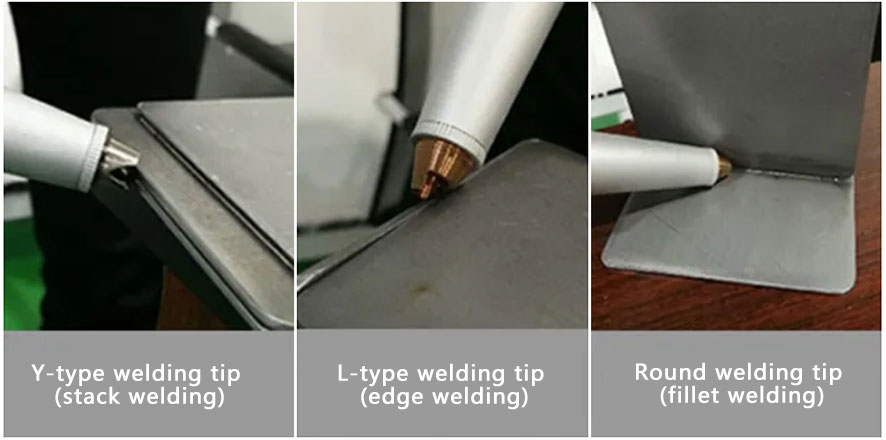

( Schematic diagram of handheld laser welding)

02 Applicable materials

It is mainly used for welding the diferent materials of aluminum sheet, iron sheet, stainless steel sheet, copper sheet and other metal sheets. And a variety of materials such as aluminum and copper, stainless steel and copper are welded together.

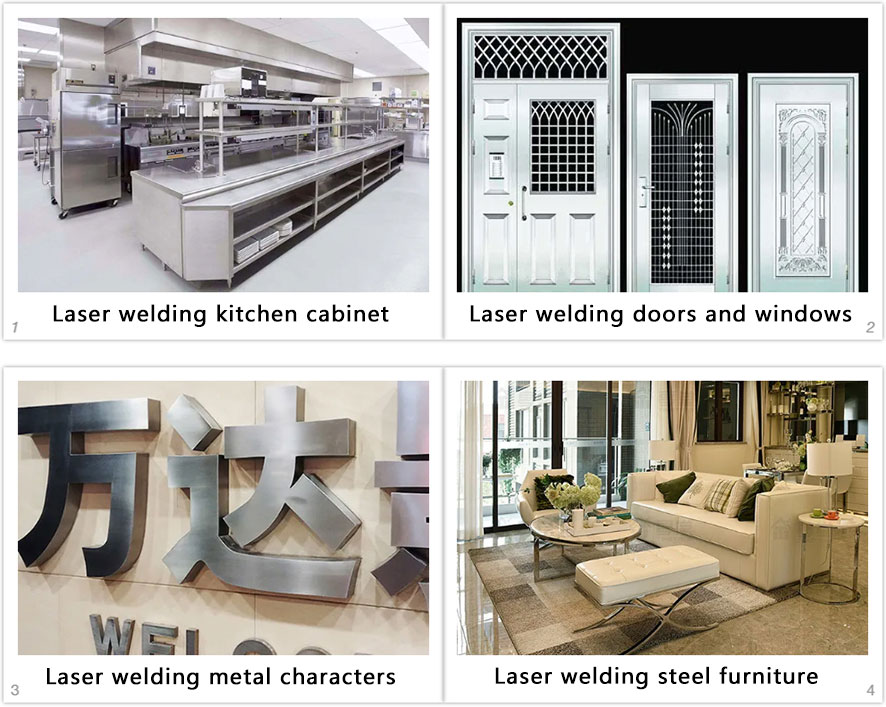

03 Process application

Handheld laser welding machine is used in the welding of cabinets such as sheet metal, chassis, water tank, distribution box, kitchen cabinets, stainless steel door and window guardrails, advertising signs, craft products, battery components, steel furniture, shelves and other fields.

04 Process advantages

High production efficiency: the laser welding speed is fast, the penetration depth is relatively deep, and the welding yield of different materials is high, which is 2-10 times faster than the traditional welding speed.

Safer and more environmentally friendly:Laser welding is environmentally friendly and safe. Traditional argon arc welding will produce a large amount of welding dust and slag, which is more harmful to the environment, while laser handheld welding is relatively less harmful to the environment.

More convenient:The hand-held welding head is light and flexible, easy to operate, and suitable for welding at various angles and shapes. It's easy to use, a single product in 30 minutes after training. Small size, integrated industrial design, flexible and light, realize indoor and outdoor long-distance welding.

The welding effect is more beautiful:During welding, the heat affected area is small, the workpiece has no deformation, no welding scars, the welding is firm, smooth and beautiful, and the subsequent grinding process is reduced.

Wide range of solderable materials:Stainless steel plate, iron plate, galvanized plate and other metal materials can be welded, and various heterogeneous materials can be welded to each other.

Sustainable work:Equipped with water cooling equipment to ensure continuous work for 24 hours.

Low labor cost:Taking argon arc welding as an example, argon arc welding requires mature welders, while handheld laser welding only requires ordinary operators. The annual labor cost of a mature welder is higher than ordinary operators. According to the efficiency of handheld laser welding, it is argon arc welding Double the calculation, and the labor cost can also be halfed. In addition, argon arc welding generally needs to be polished after welding, and handheld laser welding requires little or no need for polishing, which saves part of the labor cost of the grinder.

Welding is an important part of metal processing. It ranges from airplanes and ships to all kinds of hardware products. In the new era, there are new welding requirements. New processes and new tools are needed to meet these requirements. As a new process and new tool in the welding field, handheld laser welding machine has been unanimously recognized by many manufacturers for its advantages and performance. If you want to know our handheld laser welding machine (HW-A), fiber laser welding machine, 3D robot fiber laser welding machine, semiconductor laser welding machine, etc., please call the service hotline: 0769-8983 8888

NEXT: Laser cutting of flexible OLED screens opens the era of smart phone "folding"

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...